Smoke Clearance Time Testing regulations for isocyanate exposure can be a major area of concern, typically for workplaces that use fully enclosed CNC machines, shot blast cabinets or spray boothes.

As Occupational Hygienists, we completely understand the importance of ensuring that the workplace is a safe and healthy environment for your employees, and aid businesses with complying to The HSE Guidance Document HSG276 that states all workers involved in a process must know how long their room or enclosure takes to clear.

In the UK, smoke clearance testing is a critical aspect of maintaining a safe working environment.

This article will explore the smoke clearance time testing process, who requires such testing, the health risks associated with isocyanates in spray booths, and the current UK regulations and appropriate clearance times.

What Is Smoke Clearance Time Testing?

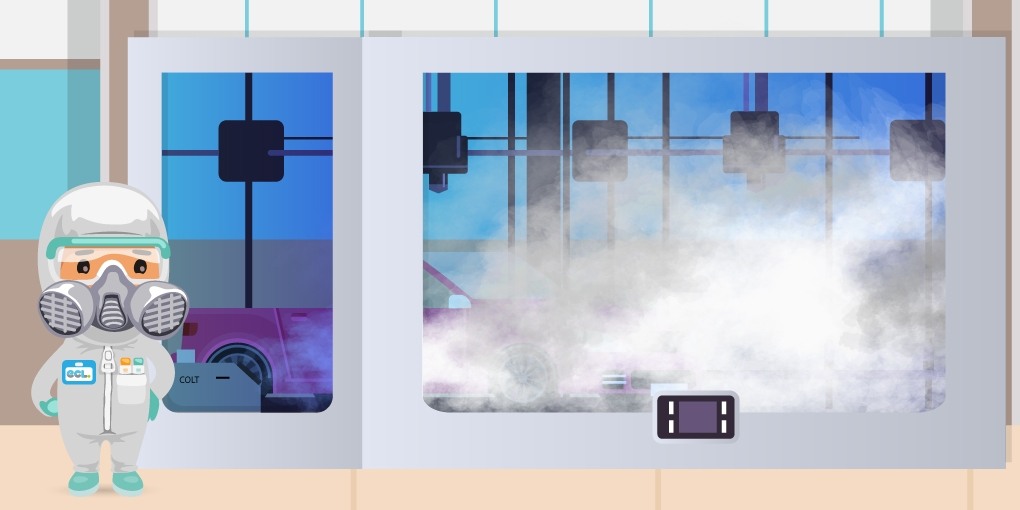

A Smoke Clearance Test is usually conducted in spray booths, but can also be conducted in other enclosed spaces where hazardous materials are used (e.g. fully enclosed CNC machines, Shot Blast Cabinets etc.) The procedure measures the rate at which smoke is removed from such enclosed areas.

A properly designed, maintained and used Local exhaust ventilation (LEV) system can remove airborne contaminants from the workplace before being inhaled by workers. The smoke clearance time test ensures that the LEV system is not only functioning correctly, but that there is also no build-up of harmful dusts, gases, mists or vapours etc.

The process involves releasing smoke into the spray booth, and then measuring how long it takes to clear the air. The time taken for any smoke removal from within enclosed systems is known as the ‘clearance time’.

To ensure contaminants are removed from an area, before opening doors of machinery, booths or rooms, or prior to removing any respiratory protective equipment (RPE), it is essential to complete a smoke clearance time test.

The clearance time is the time taken to completely remove the smoke particles from the enclosure.

A smoke clearance test can be incorporated into the regular maintenance schedule and should be completed during the Thorough Examination and Testing of an LEV System.

What Are The Benefits of Smoke Clearance Testing?

Smoke clearance testing provides several benefits for employers and employees.

Firstly, it ensures that the workplace is safe and healthy, protecting employees from the harmful effects of exposure to hazardous materials.

Secondly, it helps to identify any issues with the ventilation system (e.g. leaks), allowing for prompt repairs and maintenance to keep the system working effectively.

Finally, it provides peace of mind for employers, knowing that they are fulfilling their legal obligations and protecting the health and safety of their employees.

Who Requires Smoke Clearance Time Testing?

Smoke clearance testing is required for any workplace that uses spray booths, CNC machines or other enclosed areas that may contain hazardous materials. This includes industries such as:

- Automotive

- Aerospace

- Furniture Makers

- Manufacturing

- Wood Working

It is the responsibility of the employer to ensure that the workplace is safe and that appropriate measures are in place to protect the health and safety of employees.

What Are The Health Risks From Isocyanates In Spray Booths?

As Isocyanate Exposure is a cause of occupational asthma when spraying isocyanate-based paint, all works should be carried out within a fully enclosed spray booth supplemented by appropriately designed LEV and RPE in the form of powered air-purifying respirators (PAPR).

Isocyanates are a common component of paints and coatings used in spray booths.

Exposure to isocyanates can cause respiratory problems, skin irritation, and other health issues. Prolonged exposure can lead to more severe health problems, including asthma and lung damage.

Smoke clearance testing ensures that the ventilation system is removing isocyanates and other harmful substances from the air before they can cause harm to employees.

What Are The Current UK Spray Booth Clearance Times and Regulations?

In the UK, the Health and Safety Executive (HSE) sets the clearance time for smoke clearance testing. It is essential to ensure that clearance times meet or exceed the HSE requirements to maintain a safe and healthy workplace.

All LEV is subject to thorough examination and testing (TExT) in accordance with HSE guidance document HSG258 and COSHH Regulation 9.

It is stated within HSE Guidance Document HSG276 that all workers involved in a process must know how long their spray booth or room takes to clear. As such it is very important to ensure the residual mist has been removed before operatives remove their RPE or open access doors leading to a general workplace.

Signage stating the clearance time, date tested, person/organisation who completed the test, date of next test due should be posted at the entrance to the enclosure.

Clearance time indicators can be used to inform operatives when the clearance time has elapsed, and the booth is safe to enter without breathing apparatus.

HSG261 also states: Health and safety in the Motor Vehicle Repair and Associated industries states that ‘typically, a booth clears in less than 5 minutes, but a room can take 20 minutes or more.’ These potential differences illustrate the importance of knowing the individual clearance time for all systems.

Once a time has been confirmed, the testing can be reduced and completed as part of the statutory thorough examination and testing (TExT) in accordance with COSHH Regulation 9 and HSE Guidance document HSG258.

How Is A Smoke Clearance Time Test Conducted?

Smoke testing using a smoke generator is usually the most practical method for measuring clearance times.

As clearance times can vary (depending on filter age, enclosure size, fan speed etc.) regular tests should be carried initially to establish a ‘worst case’ time period (usually before a filter change).

To measure the clearance time a smoke generator is used and the time taken for the extract fans to fully remove all traces of the smoke recorded.

Here is a step-by-step guide on how a smoke clearance time test is conducted:

- The testing area is sealed, and all air conditioning systems and ventilation fans are switched off. Measure the clearance time with the spray booth or room empty, to avoid greasy deposits on vehicles or body parts etc. For heated booths, do the test at the normal spraying temperature. Turn the lights on full to help show up the smoke.

- Smoke is produced to fully fill the booth / enclosure, viewed from the far side of the enclosure. During smoke tests, arrange for someone else to check for any smoke leaks outside the booth/room, or ductwork. If the lighting is poor use a strategically positioned torch/Dust Lamp to ensure good visualisation of the ‘far side’ of the booth.

- A ‘pre-test’ should be carried out on any ‘first-time’ clearance time surveys so as to identify any specific locations within the booth / enclosure where smoke may settle (dead spots) as any such location should be used to ensure the actual timing of the clearance relates to the worst-case scenario for that specific enclosure.

- Switch off the fans and re-fill the booth / enclosure with smoke. Once the booth / enclosure is deemed to be full with smoke, start the extraction system and begin timing.. The room is deemed to be clear when you can see no smoke anywhere in the booth/room taking extra care to check the dead spots identified in the pre-test.

- The test is repeated to increase visualisation / timing accuracy. Round up the average measured time to the next quarter minute and record this time upon a suitable sticker (also clearly identifying the specific booth / enclosure along with the date that the testing was completed and the name of the individual completing the test).

The results should then be clearly displayed on the booth / enclosure to inform all users (ideally, post the sticker at the entrance(s) to the booth / enclosure). Alongside this, instruction and training should be given to workers on the importance of adhering to the clearance time.

How ECL Can Help With Your Spray Booth Regulation Compliance

ECL is a leading provider of Occupational Hygiene services in the UK. Our team of experienced consultants can provide a comprehensive LEV Examination, Testing and smoke clearance service, including the release of smoke, measurement of clearance times, and detailed reporting of results.

Many of our team of professional and qualified Occupational Hygiene consultants have over 20+ years of experience and can also provide advice and guidance on the maintenance of ventilation systems, ensuring that they are working effectively to protect employees’ health and safety.

ECL is also a leading provider of occupational exposure monitoring services and can provide both biological monitoring and personal exposure monitoring for isocyanate exposure.

Our team can develop and implement monitoring strategies to ensure workplace exposure limits are not exceeded and will advise on the appropriate measures that can be taken to reduce the risk of exposure and ensure you comply with COSHH Regulations.

Our air monitoring services are designed to help businesses, workers and the public stay safe from the dangers of exposure of contaminants in the workplace and external environments.

Our network of local offices across the UK, in Cardiff (Wales), Leeds (West Yorkshire), Newcastle and the West Midlands, allow ECL to provide a cost-effective service nationwide.

Contact us via our ECL Enquiry Form or call us on 01443 801215 for any queries regarding COSHH Compliance, Workplace Noise Assessments or to learn more about how we can help you maintain a safe and healthy workplace.