What Is Silica Dust?

Silica dust exposure is the single biggest risk to construction workers after asbestos exposure and the reason silica dust monitoring is so important.

Silica is a mineral. It can be found in many materials you see throughout the workplace such as sand, asphalt, concrete, soil, granite, slate, brick, and mortar. Silica can even be found in some plastics.

Dust created by cutting, grinding, chipping, sanding, carving, or drilling these materials creates minuscule crystalline silica dust particles. This finer dust is called respirable crystalline silica and is too small to see under normal lighting or with the naked eye. When this airborne silica dust is regularly inhaled over a long period of time, it can cause major health issues and even death for exposed workers.

Dust can be classified as either respirable dust or total inhalable dust. The difference being the size of the dust particles created in the atmosphere. Whilst total inhalable dust clearly exists, when referring to crystalline silica (RCS) we look at only the respirable fraction.

Why Is Silica Dust Hazardous?

The HSE estimates silica dust exposure was responsible for the death of over 500 construction workers in 2005 with an additional 4000 deaths estimated annually from COPD related to historic workplace exposures.

The reason for these figures is it only takes a very small amount of silica dust in the atmosphere to create a health hazard for workers.

As outlined in our What Is COSHH? The Complete Guide To COSHH Compliance article. The majority of lung cancers associated with silica dust may occur among workers within construction but they are also very high within the following industries:

- Oil

- Mining

- Painting

- Masonry

- Foundries

- Quarrying

- Demolition

- Warehousing

- Transportation

- Abrasive blasting

- Glass manufacturing

- Metal manufacturing

Workers in environments such as these are at a much greater risk of inhaling silica dust and therefore being affected by silica-related diseases like lung cancer, bronchitis, COPD, occupational asthma, kidney disease, and silicosis.

Silicosis

One of the dangerous effects of silica exposure is a disease called silicosis.

Silicosis is caused when small amounts of crystalline silica particles are inhaled. These fine particles can embed themselves in the lungs, which scars the tissue and reduces the lungs’ capacity to take oxygen, leading to difficulty breathing.

There is currently no known cure for silicosis, and cases can be very disabling or even on rare occasions fatal.

Lung Disease

Crystalline silica has been classified as a human lung carcinogen and can cause serious lung disease and lung cancer.

What Are The Workplace Exposure Limits For Silica?

When it is reasonable to expect significant levels of silica dust to be present, you should consider the requirement for the atmospheric sampling of respirable dust and respirable silica. Also, known as Silica Dust Monitoring.

Silica has been assigned a maximum workplace exposure limit (WEL) of 0.1 mg/m3, expressed as an 8-hour time-weighted average (TWA). It’s essential that the workplace silica dust levels are monitored and controls are used to adequately protect workers if exposure to respirable crystalline silica is higher than this WEL value.

How Can Exposure To Silica Be Reduced?

In order for employers to comply with The Control of Substances Hazardous to Health Regulations 2002 or as part of their Dust Management Plan, when carrying out a risk assessment and limiting the exposure of your workforce to silica dust, there are three things you can do, Assess, Control, Review:

Assess The Risks

First of all, you should identify all hazards, the nature of the work environment, and all tasks carried out to evaluate any potential risks. The aim should always be to prevent the risks from occurring at all, before attempting to control them. The following must be considered:

Environment: If a potentially hazardous activity takes place inside an enclosed environment the of course the risks will increase. Can these activities be moved to a different, safer environment?

Task: What materials and tools are being used to carry out work activities?

Task Duration & Frequency: How often is a particular task carried out? How long do tasks take to complete? Remember that tasks carried out more often and for a longer duration to complete will expose workers to higher volumes of silica dust.

Control The Risks

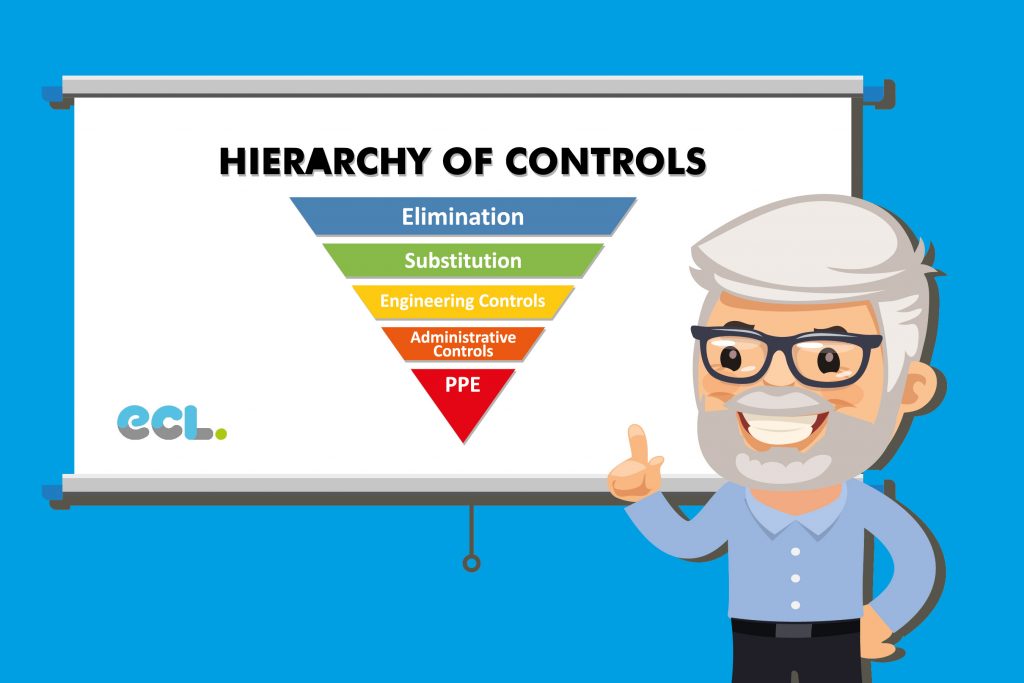

The second step should be to select the appropriate control measures to help eliminate or reduce the volume of dust created in the workplace. Control measures in line with the hierarchy of control should be used:

Eliminate: You could possibly order materials that are pre-cut to size in order to eliminate a cutting process you may use.

Substitute: Can you substitute the hazardous substance for one that isn’t hazardous? You could also maybe try using water jetting instead of abrasive blasting to reduce risk.

Engineering controls: On-tool dust extraction or general mechanical ventilation can help to eliminate the volume of silica dust.

Administrative controls: These include enforcing safe systems of work, ensuring proper housekeeping and training, and designing out particular hazards during the design stage. Administrative controls aim to alter the way employees work, in order to reduce the risks.

PPE: Personal Protection Equipment including suitable eye protection like googles, and Respiratory Protective Equipment (RPE), such as respirators should be used. PPE should be a very last resort and should only be used if you are unable to reduce the workplace exposure limits for silica dust exposure to below 0.1 mg/m³ using the other various controls above.

The controls listed above are only a few examples of effective control measures. The measures you choose to use should be tailored specifically to the work activities in your workplace.

Review The Controls

The final stage of the ACR model is to regularly review the selected controls to ensure they remain effective and are in good working order. To do this, you must ensure appropriate:

Supervision: PPE and RPE must be used correctly with employees adequately supervised.

Maintenance: All equipment and controls must be, stored properly, and regularly maintained in line with the manufacturer’s guidance.

Monitoring: Your business may be required to arrange for appropriate health surveillance such as spirometry (lung function) testing, for example, to be undertaken by employees to ensure any signs of potential work-related ill-health are identified.

Silica dust exposure will often depend upon how confined the work area is. The presence or absence of Local Exhaust Ventilation is another additional method of control that can be included to reduce risk which ECL can also help provide LEV Testing for.

Experts In Silica Dust Monitoring

Our ECL consultants are always here to help. We can develop and implement sufficient monitoring strategies to identify the maximum exposure limits of silica dust in your workplace and ensure you comply with the Control of Substances Hazardous to Health Regulations.

Our experienced and knowledgeable consultants have extensive experience in all Occupational Hygiene services, in particular Workplace Air Monitoring and the prevention of silica dust exposure in the workplace.

Get in touch with us and we can provide you with advice, information and a free quotation. Contact us via our Enquiry Form or call us on 01443 841 760 for any queries regarding our wide range of Silica Dust Monitoring, Construction Dust Monitoring, and Air Emissions Testing services.